Linecross invests in a new 8-station polyurethane soft foam carousel at its Cannock site, doubling production capacity for precision automotive components.

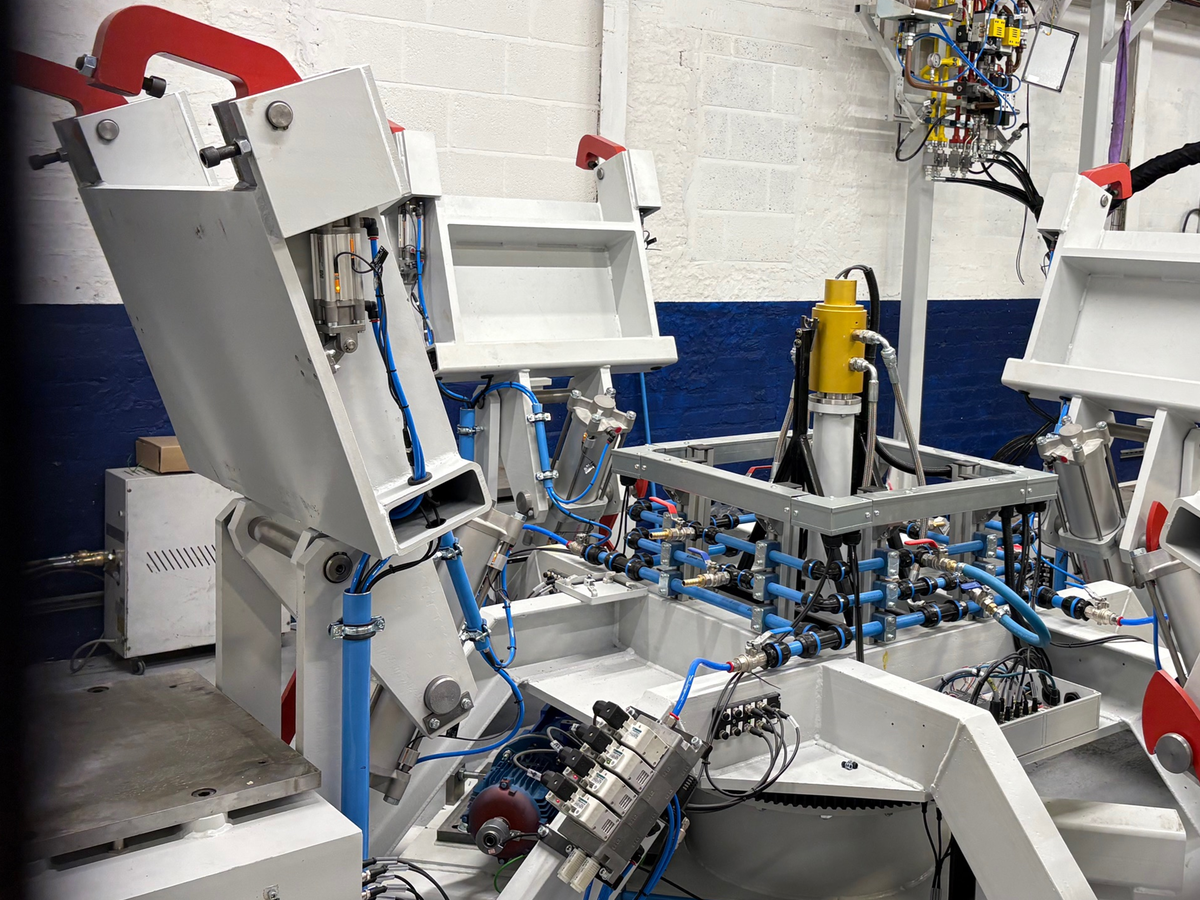

We’re pleased to announce a major investment in our polyurethane capabilities with the installation of a new 8-station polyurethane soft foam carousel at our Cannock facility. Equipped with a KUKA robot and a Cannon metering machine, the system will double our production capacity to meet growing customer demand.

The new carousel enables us to produce:

Our polyurethane technologies support a wide range of applications, including:

Flexible Soft Foam Systems

Comfort solutions for armrests, waist rails and console lids.

Integral Skin (Self-Skinning) Foam

Ideal for grab handles and energy-absorbing components.

Structural Reaction Injection Moulding (SRIM)

Lightweight, high-strength components for front-end modules, boot floors, bulkheads, instrument panels and door panels, delivering 20–30% weight reduction.

This major investment further strengthens Linecross’s capability to provide precision-engineered polyurethane solutions for the automotive sector and beyond.

web design - Dsquared