EXPLORE

With our passion and extensive knowledge of materials, processes and finishes, we work in partnership with our customers across the full spectrum of market sectors developing truly innovative solutions.

Our close relationships and collaborative work with materials suppliers and machinery manufacturers ensure that we are optimally positioned to continually explore new opportunities for technical, lightweighting and sustainable opportunities.

Linecross developed the technologies and vacuum forming processes for Harper Collective’s new sustainable luggage line, made from post-consumer recycled plastics and sea plastic materials. A project 5 years in the making this brand was co-founded by former Selfridges executive buying and merchandising director Sebastian Manes and American rapper and actor Jaden Smith

We offer a unique, proprietary moulding process for forming and back-injection moulding veneer into three-dimensional shapes. This is a wafer-thin stone veneer (approx. 1.5mm thick) but with the look/feel of solid stone. With a translucent backing carrier, we can also offer ‘back-lit’ functionality that enhances the grains and layers of the stone features.

Collaborating with Bcomp Ltd we offer sustainable lightweighting solutions for high-performance applications.Natural fibre-reinforced composites can be adapted to various applications, from sports equipment like skis and rackets to lightweight parts on supercars or even aeroplanes.

For thermoplastic automotive interior panels, the benefit is a more sustainable material and a drastic weight reduction by up to 50%, further reducing environmental impact in the use phase. It is compatible with large-scale production lines and offers unique design opportunities with colour and weave.

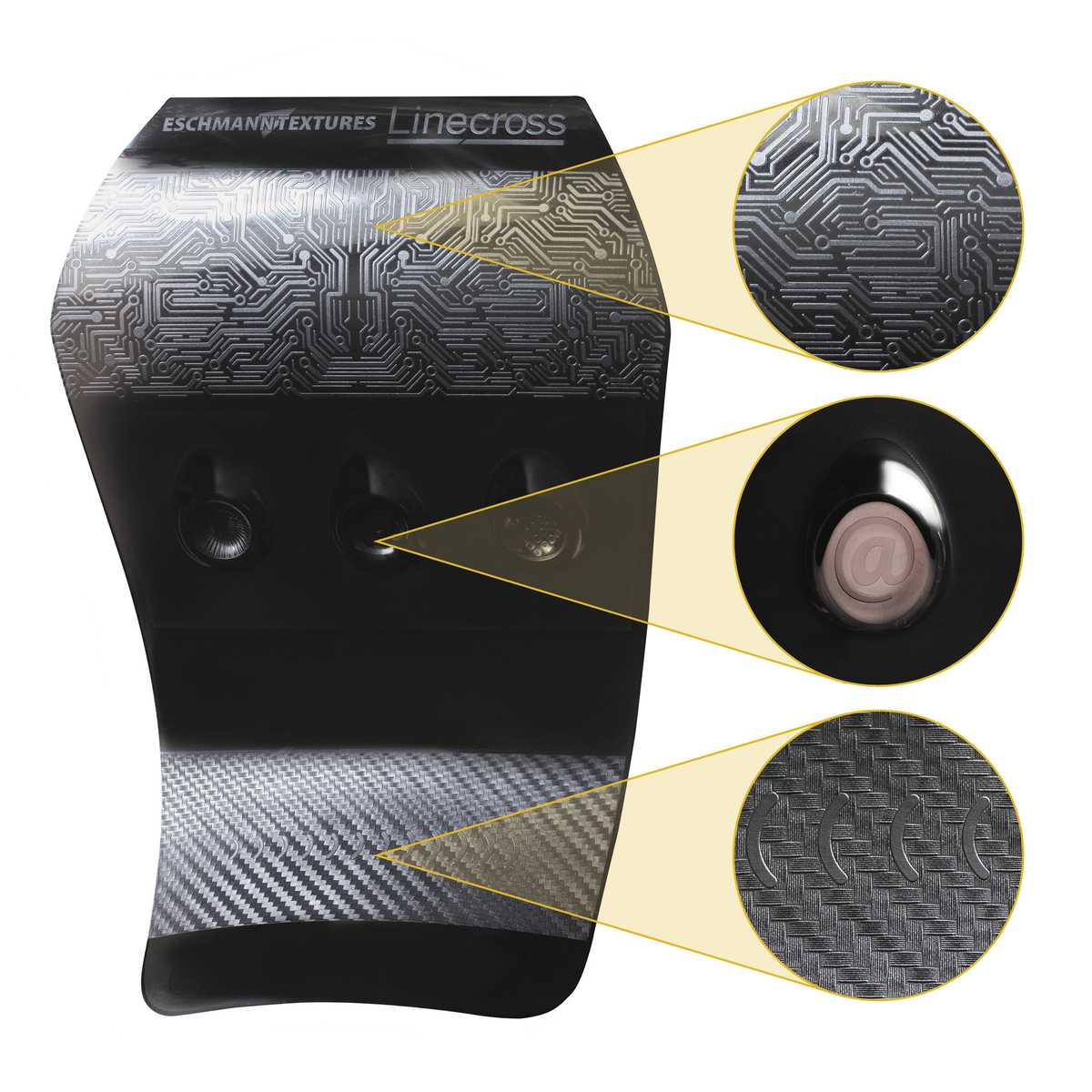

Our partnerships with Eschmann Textures UK and Albis UK offer infinite design possibilities and functional surfaces combining 5-axis laser engraving process and Alcom® material supplied through Albis UK, with Linecross’ proprietary manufacturing process.

This automotive console interior concept demonstrates how displays and buttons can be discreetly concealed and optimally illuminated. The component showcases what is infinitely possible with laser engraving when combined with Alcom LDDC piano black. The moulded quality and level of gloss mean that no painting is needed.

During normal illumination, the visual surface is a high gloss, when backlit however the concealed functional features, displays and button features which were hidden become illuminated, enabling sophisticated surfaces from a single assembly.

Our state-of-the-art 3D MetraScan from Creaform features 15 laser crosses and a high measurementrate of 1.8 million measurements per second to accelerate 3D scanning processes. This is now our go-to portable inspection tool delivering accuracy to 0.025mm for our customers regardless of the measurement setup quality.

At Linecross we provide a complete ‘concept to production’ service from customised product development to assembly and sequenced supply. Find out more about how our range of processes can support your business.

web design - Dsquared