MARKETS

We manufacture interior and exterior components for global luxury and sports car OEMS. Our extensive range of processes including polyurethane systems, compression moulding and injection moulding enables us to meet our customers’ demands for investment and component technologies by offering impartial advice, all in one place.

IP Assemblies (low volume applications) | Door Assemblies | Headliners & upper pillar trims | Lightweight foam HVAC ducting | Seat backs & valances

Fender assemblies | Windshield & Plenum finishers | Headlamp bezels Grilles | Wheel arch liners | Undertray components

PROCESSES USED: Injection moulding polymers • Polyurethane systems • PO Twin sheet foam • Thermoplastic composite laminates

Through close collaboration in process and materials innovations Linecross partner our customers successfully bringing into production new technologies to support lightweight and sustainable hybrid materials. Injection moulding recycled plastics grades in combination with lightweight foaming and gas injection technologies has enabled our global customers to significantly reduce weight and achieve their sustainability targets.

Further significant advancements in back injection moulding of compression moulded technologies with biomaterials have the potential to realise up to 50% weight savings on large surface components.

BESPOKE

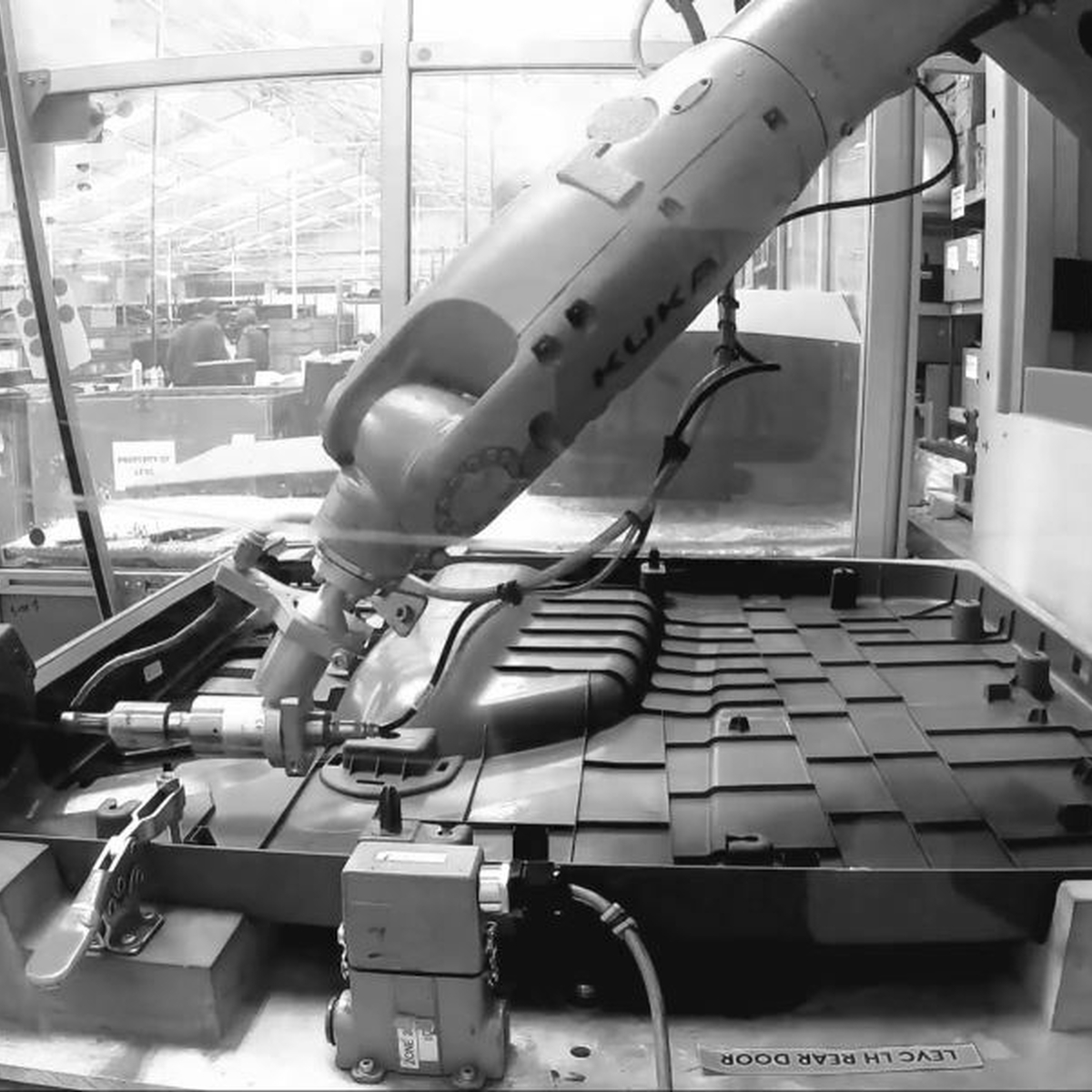

We are constantly innovating to develop bespoke solutions that go beyond our customers’ expectations. Our complete ‘concept to production’ service includes everything from customised product development to assembly and sequenced supply; supporting customers’ needs from low volume prototypes through to medium and high-volume series production.

At Linecross we provide a complete ‘concept to production’ service from customised product development to assembly and sequenced supply. Find out more about how our range of processes can support your business.

web design - Dsquared